Categories

Latest Blog

Common Maintainence of Shinho fiber fusion splicer

Common Maintainence of SHINHO fiber fusion splicer

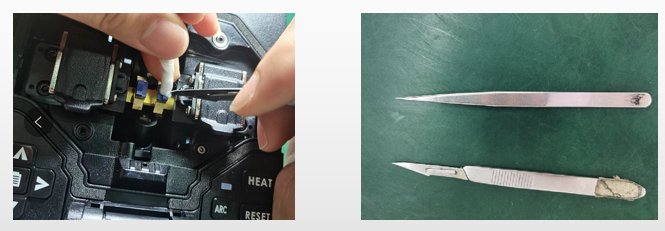

1. V groove cleaning

1) Use tweezers to wrap fibers and dip in alcohol to wipe the fixture(Figure 1), presser foot, and reflective lens(Figure 2)

2) 2.Wrap the fibers with tweezers and dip them in alcohol, scrape some fibers with the tip of the knife and wipe the V-groove in the same direction

Note:

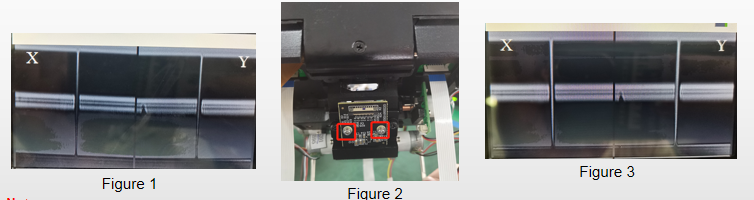

X CMOS board is at display screen side

Y CMOS board is at heater side

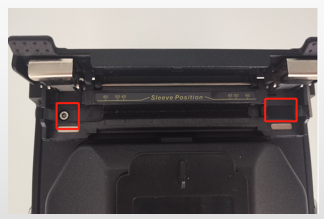

3. Heater Replacement Procedure

1) Disassemble first

2) Remove the two screws under the heater, the screw on the right is under the black sponge, first remove the sponge with tweezers, as below picture shows.

3) Replace heater housing or heater core

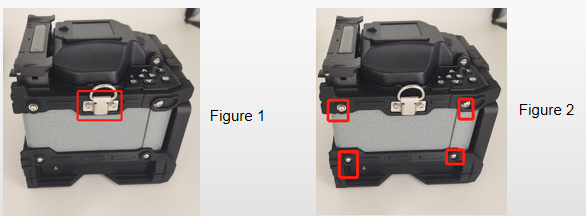

4. Machine Disassembly method

1) Remove the screws of the handles on both sides of the fusion splicer(Figure 1)

2) Remove the screws of the armor around the fusion splicer(Figure 2)

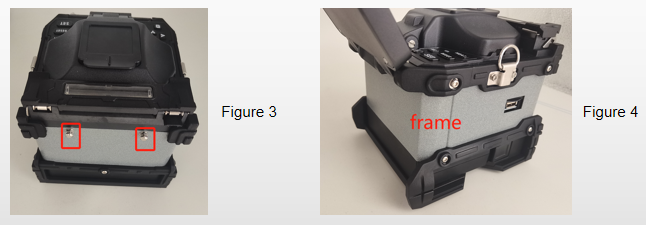

3) Remove the two screws used to hang the cooling tray(Figure 3)

4) Remove the armor, then remove the two enclosures(Figure 4)

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.