Categories

Latest Blog

Different techniques for joining optical fiber

In many applications of fiber optics, it is necessary to connect fiber ends (terminations) in some way such that light from one fiber can get into the other fiber without losing too much of its optical power. Examples are fiber lasers and systems for optical fiber communications.

There are different techniques for joining fiber ends:

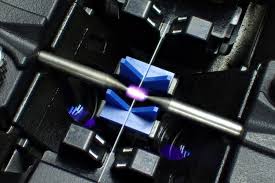

1. Permanent and stable connections with very low transition losses can be obtained by fusion splicing. Essentially, the fiber ends are fused together with a heat treatment.

The principle of fusion splicing is that the two bare fiber ends (with coatings removed) are fused together under the influence of heat. More precisely, the fiber ends are initially brought in close contact, with a small gap in between. After heating them for a short while(the heating is often accomplished with a high-voltage electric discharge) such that the surfaces melt, they are pushed together, such that the ends fuse together.

2. Semi-permanent connections can be made with mechanical splices, which are relatively simple alignment devices holding the fiber ends together. Compared with fusion splices, mechanical splices are faster and can be removed after use. The splice losses and reflection loss are of the order of 0.5 dB, i.e., significantly higher than for fusion splices and the cost per splice is higher.

3. Fiber connectors are convenient for connections which need to be released more often. Common connector types are named FC, SC and LC for single-mode applications and ST for multimode, but there are also dozens of other types. In most cases, the fiber is glued into the connector with some epoxy, and then the fiber end is polished. The transition losses of connectors are similar to those of mechanical splices, although the stability is generally lower.

In comparison with other techniques for making fiber joints, fusion splicing has some substantial advantages:

1) No other method promises lower transition losses and weaker reflections.

2) The resulting joints are very stable, i.e., no alignment needs to be maintained, and no dust can affect the joint.

3) No parts or materials are required, except for protecting the fiber after splicing.

Shinho Fiber communication Co., ltd is a professional manufacturer of fiber fusion splicer that developed 12 models for different splicing needs. The machines can joint fiber ends with very low loss and easy to operate. More info, please visit www.xhfiber.com.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.