Categories

Latest Blog

How to make a good fiber optical cable installation?

A good fiber cable installation ensures the highly effective and smooth working of the fiber optic cables. And it can spare you a lot of energy in the future maintenance and repairs, preventing endless frustrations. Therefore, it is worthy of a good installation for fiber optic cables. Then, how to make a good installation? Let's look at the main tips and get some details.

Main Tips for Fiber Optic Cable Installation

There are four main fiber optic cable installation tips or factors listed below we should pay attention to. These factors matter a lot in the whole performance of the fiber optic cable.

1. Confirm the Quality of a Fiber Optic Cable Before and After Installation

In order to avoid quality problems after installation and eliminate disputes that may be caused by cable damage, it is necessary to test the cable quality before installation. Pre-installation testing doesn't need to be too complicated or time-consuming. If the cable shows no signs of damage, the test can be performed using a continuity tracer. If all fibers transmit light, it is likely to be a good cable. If there is even a hint of possible damage to the cable, it must be tested or outright rejected.

If you find anything abnormal during the installation, a post-installation test is recommended. The abnormal issue may result from excessive pulling of the fiber cable or something other reasons. Any issue may have influence in the quality of the cable, the sooner the problem is detected and remedied, the better it is.

2. Avoid Fiber Optic Cable Waste or Exceeded Pulling

Two aspects, precise measurement and the cable control of pulling or bending, should be taken into consideration with fiber optic cable installation to avoid unnecessary disasters. Before using a fiber optic cable, you should first accurately measure the required length to maintain the minimum loss budget. When installing the fiber optic cable, please be careful of the pulling load/tensile and fiber bending radius.

The glass fiber in the cable is fragile, and the most common form of damage is fiber breakage caused by excessive tension. Therefore, the tension must be kept lower than the specified limit during installation. The following table lists the typical maximum tensile load specified by fiber cable manufacturers.

|

Application |

Fiber Count |

Short Term Maximum Tensile Load (N) |

Short Term Maximum Tensile Load (lbs) |

Long Term Maximum Tensile Load (N) |

Long Term Maximum Tensile Load (lbs) |

|

Inter-building backbone |

2-84 |

2700 |

608 |

600 |

135 |

|

86-216 |

2700 |

608 |

600 |

135 |

|

|

Intrabuilding backbone |

2-12 |

1800 |

404 |

600 |

135 |

|

14-24 |

2700 |

608 |

1000 |

225 |

|

|

26-48 |

5000 |

1124 |

2500 |

562 |

|

|

48-72 |

5500 |

1236 |

3000 |

674 |

|

|

74-216 |

2700 |

600 |

600 |

135 |

|

|

Horizontal cabling |

2 |

750 |

169 |

200 |

45 |

|

4 |

1100 |

247 |

440 |

99 |

The most important factor in fiber optic cable installation is to keep the cable's minimum bend radius. If you bend the fiber cable tighter than the minimum bend radius, it may result in increased attenuation and broken fibers. If the elements of the cable are not damaged, when the bend is relaxed, the attenuation should return to normal. The following table shows the minimum bend radius specified by cable manufacturers for fiber optic cables under tension.

|

Application |

Fiber Count |

Loaded Minimum Bend Radius (cm) |

Loaded Minimum Bend Radius (inch) |

Unloaded Minimum Bend Radius (cm) |

Unloaded Minimum Bend Radius (inch) |

|

Inter-building backbone |

2-84 |

22.5 |

8.9 |

15.0 |

5.9 |

|

86-216 |

25.0 |

9.9 |

20.0 |

7.9 |

|

|

Intrabuilding backbone |

2-12 |

10.5 |

4.1 |

7.0 |

2.8 |

|

14-24 |

15.9 |

6.3 |

10.6 |

4.2 |

|

|

26-48 |

26.7 |

10.5 |

17.8 |

7.0 |

|

|

48-72 |

30.4 |

12.0 |

20.3 |

8.0 |

|

|

74-216 |

29.4 |

11.6 |

19.6 |

7.7 |

|

|

Horizontal cabling |

2 |

6.6 |

2.6 |

4.4 |

1.7 |

|

4 |

7.2 |

2.8 |

4.8 |

1.9 |

3. Do Not Exceed the Maximum Vertical Rise

Each vertical fiber optic cable has a maximum vertical rise, representing the maximum vertical distance the cable can be installed without intermediate support points. The maximum vertical rise is a function of the cable’s weight and tensile strength. Make sure not to exceed the maximum rise when cabling.

4. Do Not Mix Fiber Optics and Use Paired Fiber Optic Equipment/Accessories Separately

Single mode fiber and multimode fiber are usually incompatible because of the large gap between the two in fiber core sizes. The multimode fiber has a core size of 62.5μm or 50μm, while the single mode fiber core is only 9 μm. If you tried to use multimode fiber over a single mode fiber link, the larger core size of the multimode fiber cable would cause big attenuation loss easily. Therefore, you’d better not mix the two types of fibers. Similarly, you should not mix different accessories such asPC, APC, UPC fiber connectorstogether as well.

In addition, you should try your best to avoid using fibers of various core sizes even if they are the same type. For example,mixing 62.5μm and 50μm multimode fibersis not recommended even if they may be compatible with each other.

5. Other Tips on Fiber Optic Cable Installation

Except from the main fiber optic cable installation tips, the further details should also be paid attention to.

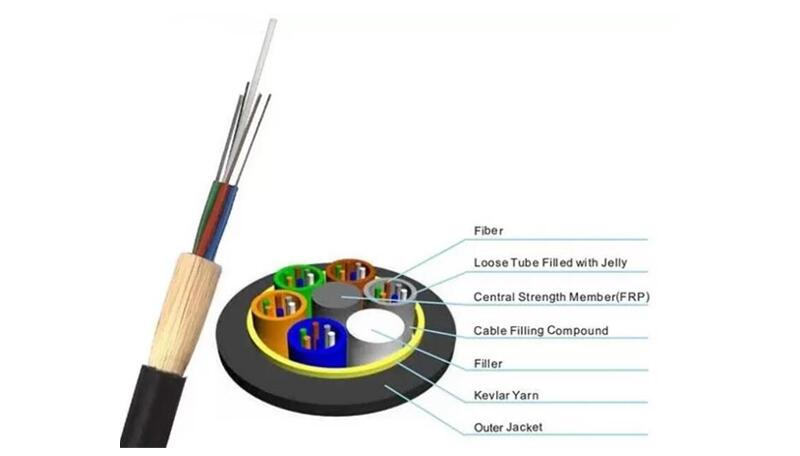

Never directly pull on the fiber itself: fiber optic cables have Kevlar aramid yarn or a fiberglass rod as their strength member. You should pull on the fiber cable strength members only.

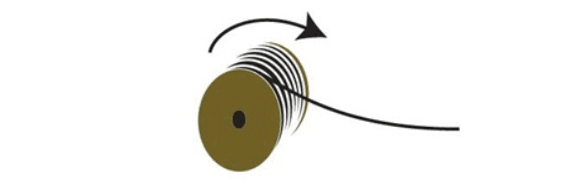

Roll the cable off the spool instead of spinning it off the spool end: spinning the cable may put a twist in the cable for every turn on the spool. The twist can stress the fiber and may cause the fragile fiber cable to break.

Use fiber optic cable lubricant: it is important to use lubricant compatible with the cable jacket material when installing in conduits. The lubrication can reduce the pulling load and the chance of breakage.

Observe the temperature range while operating: you should install the cable where the temperature is within the normal operating range. Violation of the temperature range can cause excessive attenuation.

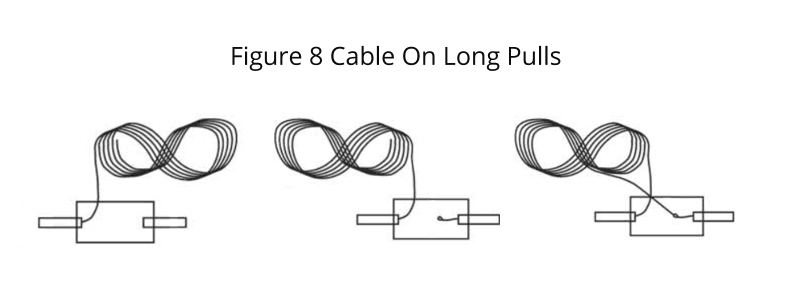

Place the cable correctly: when pulling the fiber out of a section, coil the cable on the floor in a figure 8 pattern to avoid twisting.

Safety precaution: do not look into the fiber unless you are sure that there is no laser light in the fiber. For extensive work with fiber optics, safety glasses with IR filters are recommended.

from https://community.fs.com/

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.