Categories

Latest Blog

Polarization-maintaining Fiber

Definition: Polarization-maintaining Fiber is specialty optical fibers with strong built-in birefringence, preserving the properly oriented linear polarization of an input beam.

Principle of Polarization-maintaining Fibers

Optical fibers always exhibit some degree of birefringence, even if they have a circularly symmetric design, because in practice there is always some amount of mechanical stress or other effect which breaks the symmetry. As a consequence, the polarization of light propagating in the fiber gradually changes in an uncontrolled (and wavelength-dependent) way, which also depends on any bending of the fiber and on its temperature.

The mentioned problem can be fixed by using a polarization-maintaining fiber, which is not a fiber without birefringence, but on the contrary a specialty fiber with a strong built-in birefringence (high-birefringence fiber or HIBI fiber, PM fiber). Provided that the polarization of light launched into the fiber is aligned with one of the birefringent axes, this polarization state will be preserved even if the fiber is bent. The physical principle behind this can be understood in terms of coherent mode coupling. The propagation constants of the two polarization modes are different due to the strong birefringence, so that the relative phase of such copropagating modes rapidly drifts away. Therefore, any disturbance along the fiber can effectively couple both modes only if it has a significant spatial Fourier component with a wavenumber which matches the difference of the propagation constants of the two polarization modes. If this difference is large enough, the usual disturbances in the fiber are too slowly varying to do effective mode coupling.

Ways of Realizing Polarization-maintaining Fibers

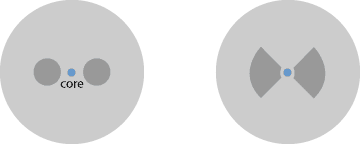

A commonly used method for introducing strong birefringence is to include two (not necessarily cylindrical) stress rods of a modified glass composition (with a different degree of thermal expansion) in the preform on opposite sides of the core (Figure 1). When a fiber is drawn from such a preform, the stress elements cause some mechanical stress with a well-defined orientation. Another variant of that approach is to have an elliptical cladding of different glass around the core.

Figure 1: Polarization-maintaining PANDA fiber (left) and bow-tie fiber (right). The built-in stress elements, made from a different type of glass, are shown with a darker gray tone.

Another technique is to use an elliptical core causing so-called form birefringence [1]. Here, the elliptical form itself, even without any mechanical stress, produces some level of form birefringence.

Applications

Polarization-maintaining fibers are applied in devices where the polarization state cannot be allowed to drift, e.g. as a result of temperature changes. Examples are fiber interferometers, fiber-optic gyroscopes and certain fiber lasers. A disadvantage of using such fibers is that usually an exact alignment of the polarization direction is required, which makes production more cumbersome. Also, propagation losses are higher than for standard fiber, and not all kinds of fibers are easily obtained in polarization-preserving form.

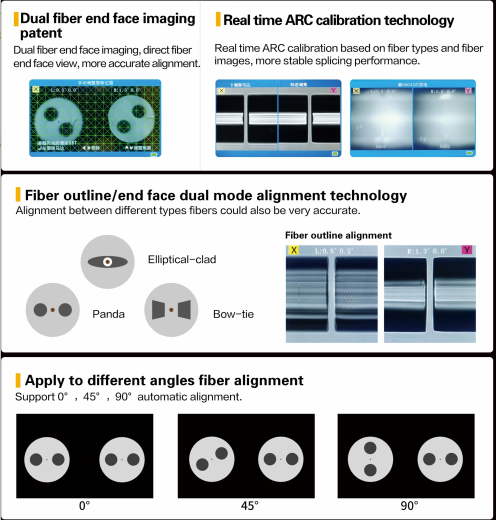

Machine for connecting PM Fibers

SHINHO S-12 Polarization Maintaining (PM) fiber fusion splicer is with the latest accurate fiber alignment technology, it has very stable performance and low fusion loss, it is specially designed for Panda ,bow-tie and elliptical fibers.

If you are interested in fiber splicing machine, please contact Shinho Fiber Communication Co., ltd for more information.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.