Categories

Latest Blog

The importance of polarization-maintaining(PM) fiber

What is Polarization maintaining (PM) fiber?

In practice, the conventional optical fiber in the production process, will be affected by external forces and other reasons, so that the fiber thickness is not uniform or bending, so that it will produce birefringence phenomenon. When the fiber is subjected to any external interference, the polarization of light transmitted in conventional fiber will become chaotic.

The application of PM fiber can solve the problem of polarization state change, but it does not eliminate the birefringence in the fiber, but through the design of the optical fiber geometry size, to produce more intense birefringence, to eliminate the influence of stress on the polarization state of incident light.

How does PM fiber affect the birefringence in the fiber?

In the drawing process of PM fiber, when linearly polarized light is transmitted along one characteristic axis of the fiber, part of the optical signal will be coupled into another characteristic axis which is perpendicular to it, and finally the polarization extinction ratio of the outgoing polarized light signal will decrease, thus affecting the birefringence effect.

How to make polarization-maintaining fiber?

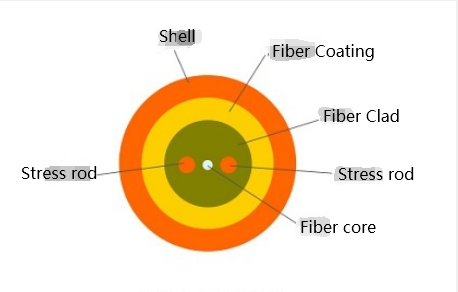

The common method of introducing high birefringence can be achieved by introducing geometrically symmetric non-uniform stress into the fiber core of the prefabricated rod by adding two stress rods of improved glass composition to both sides of the fiber core. The stress polarization maintaining fiber mainly relies on the difference of the thermal expansion coefficient between the stress rod and the fiber core to produce thermal stress, which leads to the change of the refractive index of the material under the action of thermal stress, thus producing the birefringence effect. Another option is to use an oval core, which in itself produces a degree of shape birefringence, even without mechanical stress.

The stress rod is parallel to the optical fiber core, and the applied stress produces birefringence in the optical fiber core, which is beneficial to the polarization propagation of light in only one direction, so as to maintain the polarization maintenance work. Panda type stress rod is cylindrical, while bow tie type uses trapezoidal prism stress rod. Generally speaking, the polarization state of polarization-maintaining fiber depends on the incident state of polarized light, which requires coupling alignment between polarization state of polarized light and fast and slow axis direction of polarization-maintaining fiber. To ensure that the two optical fibers transmit at a high extinction ratio, it is necessary to ensure that the stress bars are aligned when the polarization-maintaining optical fibers are terminated through the fiber connector.

In order to solve the above problems, Shinho independent designed the first full automatic PM fiber splicing machine(PM S-12) in China, it can do Endview and Profile observation and alignment, make the stress rods aligned with low loss. And the extinction ratio is good as 32dB.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.