Categories

Latest Blog

What is a Fiber Optical Fusion Splicer and How To Splice Two Fibers

What is a fiber optical fusion splicer?

Fiber fusion splicer is to use high-temperature heat generated by electric arc and melt two optical fibers together at their end faces,to form single long fiber.More precisely, the fiber ends are initially brought in close contact,with a small gap in between. After heating them for a short while such that the surfaces melt, they are pushed together, such that the ends fuse together.Fusion splicer is a long-used tool in outside fiber-optic installation,and in recent years has been more commonly used in indoor environments as well.

How to splice two fibers?

Step 1 Preparation of fiber end face

Prepare two optical fibers,which an optical fiber is set into the heat shrink tube.Clenched fiber cleaver, place the fiber into the tooth of clamp by the left hand, reserve bare fiber 30 to 40 mm stripped fiber coating. Use a cotton ball dipped in anhydrous alcohol (purity>99%) wipe optical fiber coating layer that residual debris.

Step 2 Cut two fibers

Put the cleaned fiber into the cutter positioning groove, the edge alignment of the fiber coating cutter ruler “13” scale outside (the scale is greater than 13). Close small platen, requiring that the bare fiber straight on the left and right rubber on the chopping block. Together close the large plate, and push the cutter blade slider to the other end to cut off the fiber.

After Cutting, open the large platen to take away cutting broken fiber into the waste fiber storage box. (Broken fiber has a great harm to human health, so, please be sure to collect and chop broken fiber). Open the small platen, and carefully take out the cut end face fiber. Don’t make the fiber cross section touching any other objects, in order to avoid damage or contamination end face.

Step 3 Fiber Clamping

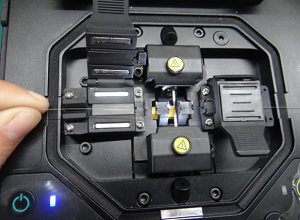

Open the windproof cover and the two side fiber platens, then, put the prepared fiber into V-groove through the locating slot. Make sure that the fiber end face should be located between V-groove edge and two electrodes.

Please operate carefully and don’t let the fiber end face touch any other object. Then close the large platen to fix optical fiber, which should be placed horizontally in the V-groove, without upturned phenomenon. If clamping failed, you can lift fiber carefully and repeat the operation above until the fiber clamping is qualified.

Step 4 Optical Fiber Fusion

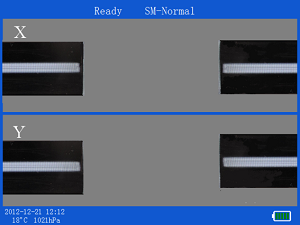

After clamping, the machine is in ready state, as shown below. If in "Automatic" splice mode, auto splice begins as soon as the windproof closed. If in "Manual" splice mode, user must press the "SET" button to run the splice routine.

Press "SET" to start the splice procedure. The machine drives the motor, which will promote both sides of fibers to the middle of the screen, judging the fiber end face whether meet the requirements. If qualified, turn to the next process, otherwise show a tip of bad end face and stop.

After judgment, alignment motor will adjust fiber position to make both sides of fibers align in three-dimensional. At last, the electrode discharge arc to fuse fiber. When fusion completed, the machine will give the loss estimates, and have a tension test if needed.

Step 5 Heat-shrinkable

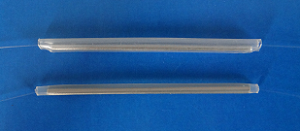

Optical fiber fusion point is really fragile and easily broken, so, you need protection by using heat shrinkable. Open the windproof cover, large platen and heater cover. Gently remove fiber, and don’t bend fiber greatly to avoid the fusion point broken.

Move heat shrinkable tubing to the fusion point, which must be in the middle. Then, place heat shrinkable tubing in the middle of the heating furnace. The heater begins heating as soon as heating furnace closed.About 20 seconds later, heating shrinking has completed.

Step 6 Cooling

The heat shrinkable tubing after heating is in high temperature, and need cooling. Hang the cooling tray on the carrying handle. So, after heating, pull out the fiber from the heating furnace to the cooling tray by hands. About 1 minute later, it cools to the ordinary temperature.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.