Categories

Latest Blog

Calculation principle of real loss of optical fiber fusion splicer

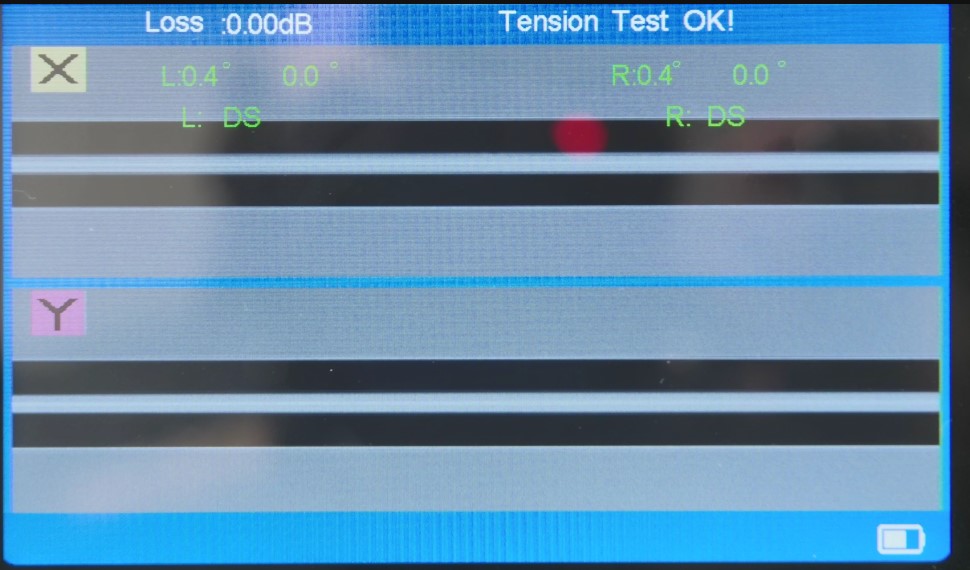

The optical fiber fusion splicer will show estimated loss after splicing, this value is an important data of the quality of the spliced fiber, but this data is not the exact loss, it is just an estimated value.

The loss of splicing mainly comes from the eccentricity of the optical fiber, because light propagates in the core. If there is a deviation in the core of the splicing point, the light will inevitably be attenuated at this point.

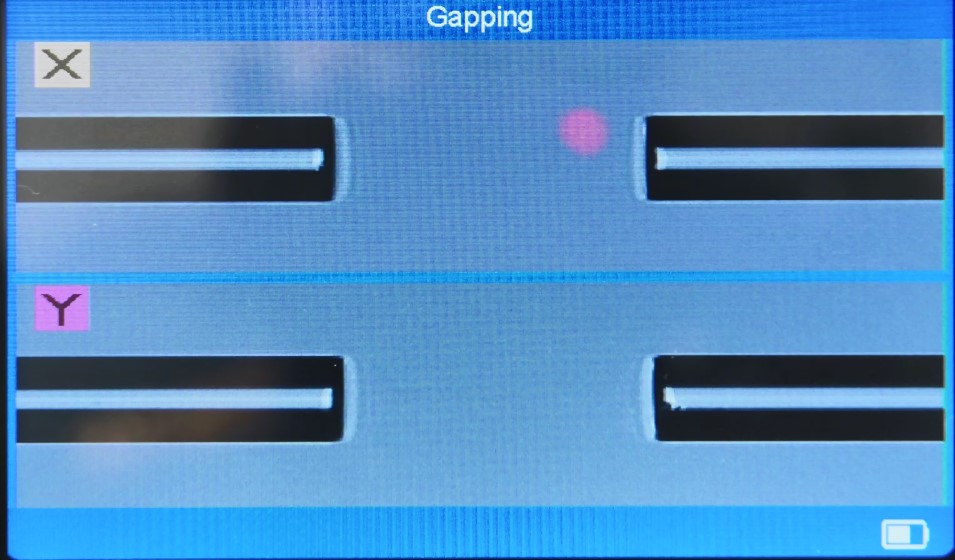

As shown in the three pictures above, the fusion splicer will perform core splicing before splicing to ensure that the cores of the left and right optical fibers are spliced in a straight line. After the fusion is completed, the ideal situation is that the cores of the left and right optical fibers are still in On the line, but if the eccentric situation shown in the third picture occurs, there will be loss.

The main reasons for the loss are: eccentricity, inconsistency in mode field diameter, and the generation of air bubbles.

Eccentricity ,reasons:

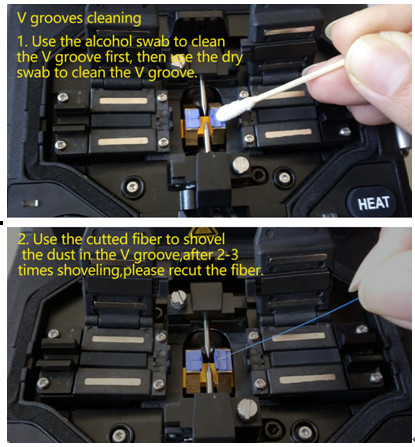

1. Fiber foot is dirty or broken

2. Dirty in V groove

3. Aligning part damaged

4. Pushing motors problem

MFD deviation,reasons:

1. MFD mismatch caused by poor discharge power

2. Unavoidable splice losses

3. G652-G655 or G652-G657

Bubbles appear,reaosn:

1. poor discharge or too short time of discharge

2. Dirty on fiber end-face

3. Uneven of fiber end-face

Then the fusion splicer obtains the final loss estimation result through a series of calculation procedures. The loss finally displayed on the fusion splicer is the sum of the above conditions.To avoid loss, it is necessary to eliminate the possibility of problems from the source and standardize the operation steps.

In summary, the estimated loss displayed by the fusion splicer after splicing mainly depends on the calculation after the observation, so the accuracy of the observation becomes the key to the accuracy of the display.

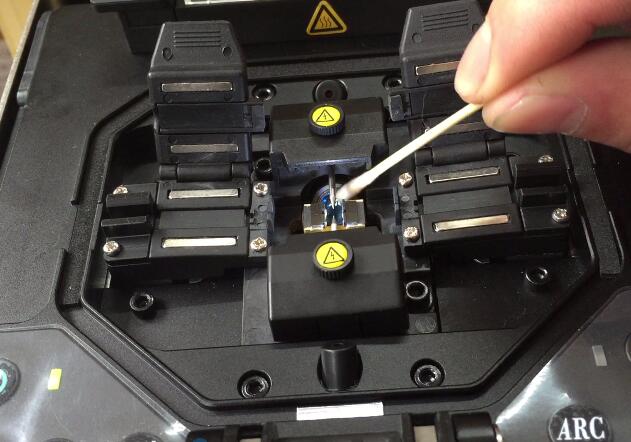

In fact, our fusion splicer will inevitably be contaminated with dust after long-term use in harsh working environments. The dust attached to the display accessories, such as the objective lens and the reflector, will greatly affect the accuracy of the estimation, and it needs to be cleaned regularly. The specific cleaning method is as follows:

Also choose a high-precision fiber cleaver to cut the fiber end face and use the fusion splicer correctly will also reduce the loss.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.