Categories

Latest Blog

How to Choose Fiber Cleavers?

Nowadays

we could see many different types of fiber cleavers in the market, some even

only sold at $10. Is there any difference between fiber cleavers? Did the fiber

cleaver I chosen really can work for me correctly? Today let’s talk about it.

First, what is fiber cleaver?

When we

need to join two optical fibers together, we usually use mechanical splice or

fusion splice. Both optical fiber splicing techniques require that the fiber

tips are a smooth end face that is perpendicular (90°) to the fiber axis.

And an

optical fiber cleaver is the tool to cut (called cleave in the fiber optic

industry) the fiber in such a good way. it is very necessary to use fiber optic

cables with clean and smooth end face. The fiber optic cleaver is a crucial

tools for low-loss and low-reflectance fiber optic splices or terminations,

especially when using the pre-polished connectors with internal splices. It is

the key to quality connectors and splices.

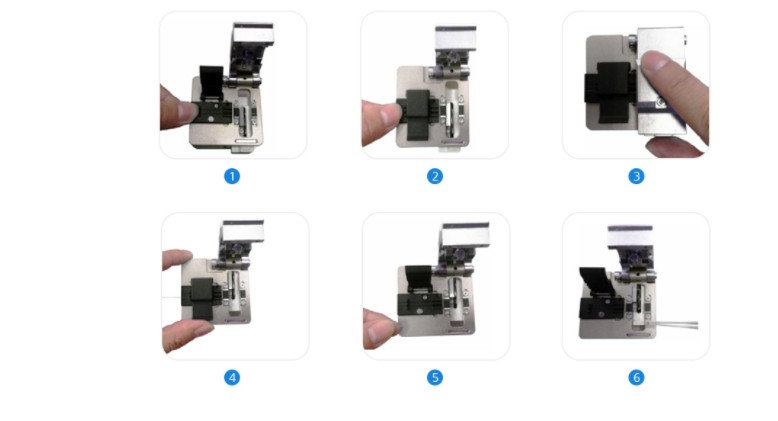

Step 1:

Open the body cover and put the stripped fiber on the v-groove.

Step 2:

Close the holder cover.

Step 3:

Close the cover and move the slider forward to cleave the fiber.

Step 4:

Open the cover and check the cleaved fiber.

Step 5:

Open the holder cover and take out the cleaved fiber.

Step 6:

Remove the chip of cleaved fiber with a pair of tweezers or brush.

We

usually use the desktop cleavers in the industry. They use a diamond or

tungsten wheel/blade to provide the nick in the fiber. Tension is then applied

to the fiber to create the cleaved end face.They can produce repeatable results

through thousands of cleaves by simply rotating the wheel/blade accordingly.

Although more costly, precision cleavers can cut multiple fibers at one time

with increased speed, efficiency, and accuracy.

Capable

of cleaving multimode, single mode, single fiber high precision desktop

cleavers provide up to 48,000 single cleaves .Most desktop high precision fiber

cleavers are packaged with fiber scrap collectors.

One step

automatic fiber cleaver:

Like

CT-30, Shinho X-55B, These cleavers not only collect the fiber scraps, but also

store the scraps in internal trash bins, ultimately saving cleaning and safe

disposal time for the technician.

As a

standard safety practice, fiber shards should always be collected and disposed

of properly, since fiber can easily embed into the skin. Due to automated

scoring mechanisms, cleavers can now complete a cleave and reset themselves for

the next cleave in one or two steps, streamlining the cleaving process while

perfecting the quality and reliability of the cleave.

The fiber cleaver is a tool commonly overlooked when making a fusion splicer

purchase. Just ask any technician who has worked the late shift or faced that

rush splice job how stressful a poorly functioning cleaver can be. Since a

perfectly smooth optical fiber end face is crucial for a successful low-loss,

low-reflectance fusion splice or termination, the following tips are useful

when making a new cleaver selection.

THINGS

TO ASK BEFORE BUYING A FIBER CLEAVER

1. Select a

cleaver that meets your application requirements.

Cleavers

that are designed for fusion splicing require a low average angle that is one

degree or less, while cleavers appropriate for mechanical connectors require

angles below three degrees. Determine whether you require a single- or multi-fiber cleaver that can precisely cleave one to 12 fibers at a time.

2.Purchase

your cleaver from a reputable manufacturer or distributor.

Tempting

some platform offers of cleavers at highly discounted prices abound on

the Internet. As with fusion splicers, there are a host of illegitimate

knock-offs that replicate the body, look, and branding of the leading

manufacturers’ cleavers. Look at the inner components and you’ll likely find

cheaply made parts and blades with inferior metal alloys that can compromise

your splice or break down during the job.

By

purchasing from reputable manufacturers, you’ll enjoy manufacturer support and

warranties; service for periodic maintenance and cleaning that extends the life

of the cleaver; and a cleaver made of the best durable metal materials.

3.Think

twice before purchasing a cleaver built into a splicer.

The

downside to these built-in cleavers is that if either the cleaver or splicer

requires maintenance, the technician loses two valuable tools, which can hold

up the job at hand.

4.Purchase

a cleaver with the latest automation features that save time.

Cleavers, like fusion splicers, continue to

evolve with new and improved features, such as automated fiber scrap

collection, automated scoring mechanisms, and the latest automatic blade

rotation technology.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.