Categories

Latest Blog

SHINHO X-900 Fusion Splicer User Guide

Fusion splicer is mainly used in the construction of optical cable lines, line maintenance, emergency repairs, production testing of optical fiber devices, and research and teaching in scientific research institutes for major operators, engineering companies, and enterprises and institutions.

Optical fiber fusion splicing machine uses high-voltage arc to melt the cross-sections of two optical fibers, and at the same time, uses high-precision motion mechanism to gently advance the two optical fibers into one, so as to realize the coupling of optical fiber mode fields (fiber splicing)

1. Appearance and Features of X-900

X-900 Fiber fusion splicer equipped with precise six-motor alignment structure with the latest fiber core to core alignment technology, it had specially designed optical lens and software algorithm, so it can accurately identify the type of fiber and automatically select the matching splicing mode to ensure the splicing quality. It is suitable for different fiber optical projects , including backbone, trunk construction and device production etc.

Features:

2. Operation of X-900

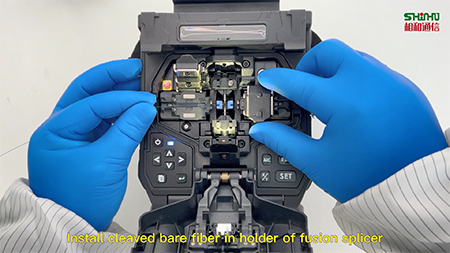

Preparation tools of splicing :X-900 fusion splicer, fiber cleaver X-50B, fiber stripper X-2001,alcohol spray bottle, bare fiber.

Step 1: Prepare the fiber to be cleaved and cleaned, put it in the fiber holder.

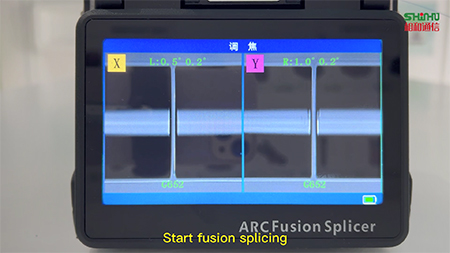

Step 3: Close wind-proof cover, start splicing.

Step 4: splicing finished.move the sleeve to the splicing point, put it into heater, starting heating until the light power off.

The above is the detailed operation of Shinho X900 fiber fusion splicer tutorial.

Shinho Communication is a high-tech enterprise with ISO9001 quality management system certification and ISO14000 certification, specializing in providing various optical fiber processing solutions. With a rich product line, the products are all independently developed and have complete intellectual property rights.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.