Categories

Latest Blog

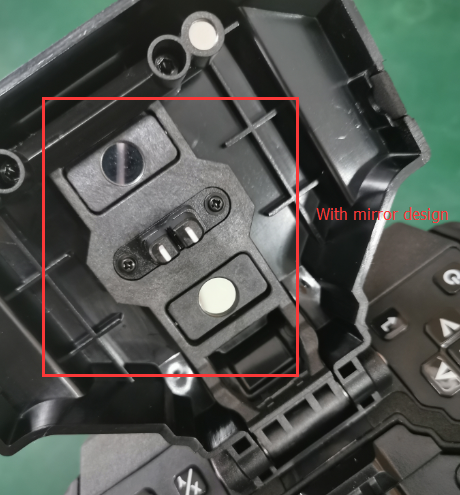

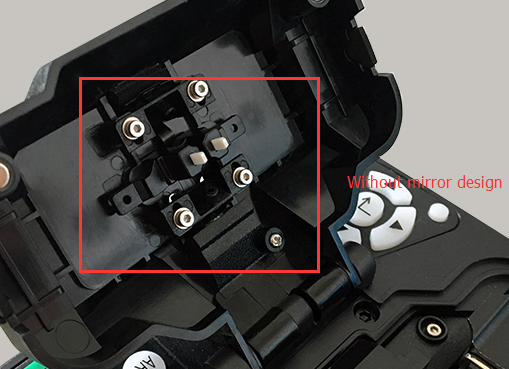

Difference between mirror design and without mirror design for a fusion splicer

What is the difference between mirror design and without mirror design for a fusion splicer?

Currently fusion splicers have two types structures for fiber imaging. One is with reflective mirror design, the other is without reflective mirror design? Which one is better?

|

|

With mirror design

|

Without mirror design |

|

Advantages |

Classic design, stable and durable |

1.The optic path could be shorter, which make the windproof cover size smaller, then the machine size could also be smaller, easy to carry for users; When operating in wet environment, or from a low temperature environment to a higher temperature, the mirrors may become misty,which will affect the fibers aligning and splicing. No-mirror design could prevent that. |

|

Disadvantages |

Easily affected wet environment, temperature changes, the mirrors may become misty, which will affect the fibers aligning and splicing. It needs to clean it up. |

The led lights cable may get worn or damaged after long time windproof cover opening and closing. Because the cable is passing through the windproof cover, so when the cover is opened and closed too frequently, that may wear the cable after a long time using. Not only us, such as INNO, Fujikura without mirror design also has such problem. |

Shinho S-16 fusion splicer is a with mirror design, while X-700 fusion splicer is a without mirror design. For moredetails, welcome to visit the www.xhfiber.com.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.