Categories

New Products

LDC-100 Large Diameter Optical Fiber Cleaver * Applicable to cladding diameter 80μm~1250μm fibers * Vacuum pump V-groove convenient to put fiber * Durable blade, lifetime more than 20000 times * Data storage 4000 groups * User friendly GUI menu, easy to operate more

S-22 Multi-Core Fiber Fusion Splicer The 1st Fully Automatic Multi-core Fiber Fusion Splicer in China more

Polarization Maintaining (PM) Fiber Fusion Splicer S-12 *Suitable for SM/MM/PM fibers splicing * Core to core alignment, low splicing loss * Endview and Profile observation and alignment * Arc automatic calibration and splicing * PM fiber 45 and 90 degree alignment * Applicable to variety fibers splicing, such as Panda ,bow-tie and elliptical fiber more

S-37 LDF Speialty Fiber Fusion Splicer SHINHO S-37 is the latest model we developed, it could splice fiber cladding diameter from 125 to 680μm with low splice loss. We equipped the machine with 3 different fiber holders, and 2 pairs of spare electrodes. more

Core to Core Alignment Fiber Fusion Splicer X900 Six motors fusion splicer, real core to core alignment technology. Typical splicing time: 6-12 seconds, fast splicing 6 seconds Typical heating time: 18s heating, identify fiber types automatically. Typical splice loss:G651: 0.01dB; G652: 0.02dB; G653: 0.04dB; G654: 0.04dB; G.655:0.04dB; G657:0.02dB. Battery Capacity: 5200mAh Li-battery, typical 300 cycles splicing and heating. Used for WAN/ MAN/ Telecommunication projects. more

Robust Multi Function ARC Fusion Splicer S16 76cm dropping anti-shock, IP5X dustproof and IPX2 water resistant Touch screen display, combined with keypad operation Multi function holder for bare fiber, patch cords, drop cable etc. Fast splicing and heating, automatic ARC calibration. more

SHINHO X-18 Ribbon Fiber Thermal Stripper Shinho X-18 Thermal Stripper is a newly developed hand-held thermal stripper, specially designed for nondestructive thermal stripping of the jacket of ribbon cable up to 12 fibers. A good and reliable tool for ribbon fiber splicing work. more

High Precision Fiber Optic Cleaver X-50D Small size& light weight, easy to operate. High precision and stable performance. More than 48000 time blade life,fiber cleaved length 5~20mm. High quality material more

How an OTDR works

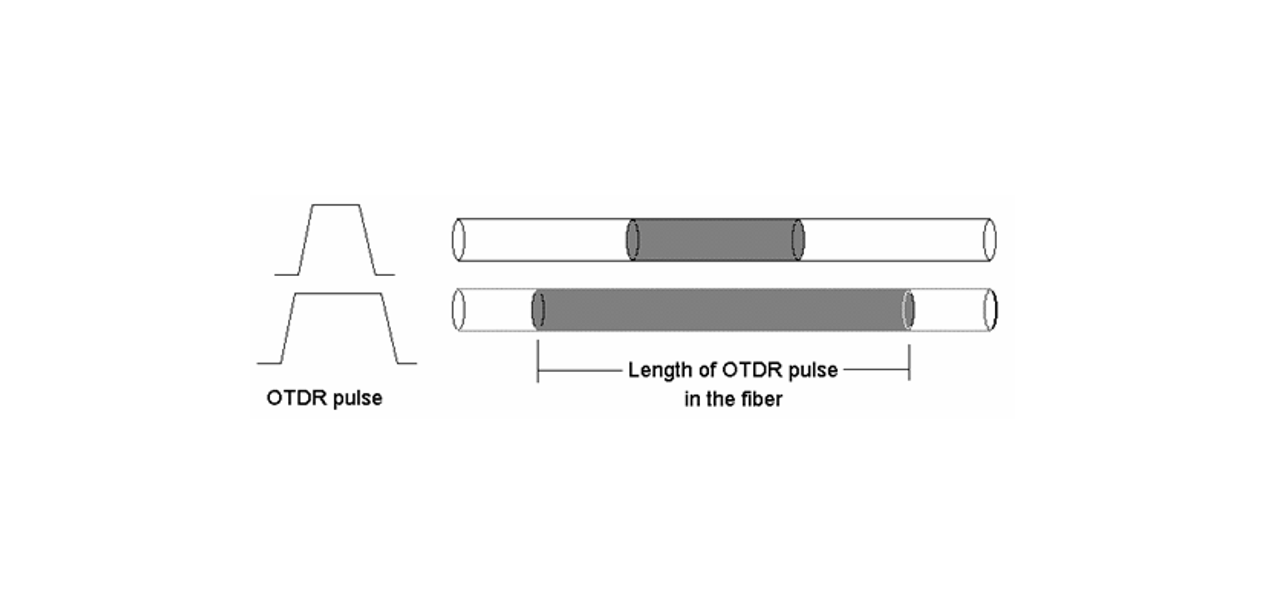

An OTDR works like radar—it sends pulses along an optical fiber and looks for a return signal, creating displays called “traces” or “signatures” from fiber measurements. It simply connects one end of the fiber, and the OTDR calculates fiber attenuation, uniformity, splice, and connector loss, then provides graphical traceability. Its ability to locate and measure reflectivity and loss makes the OTDR the device for troubleshooting and fault location. It also sends pulses of light energy from a laser diode to one end of the fiber. The photodiode then measures the returning light energy over time and converts it to an electrical value sampled, amplified, and displayed graphically on the screen.

The amount of light scattered back to the OTDR is proportional to the backscattering of the fiber, the peak power of the OTDR test pulse, and the length of the emitted pulse. You can increase the pulse peak power or width if you need more backscattered light to get good measurements.

High-accuracy loss measurements are critical for fiber optic infrastructure to support critical 5G and IoT services. Therefore, the measurements need to be extremely reliable and accurate. OTDR is an important investment to ensure the reliability of fiber optic networks. In today’s ever-evolving communications environment, you can be confident that top-notch and reliable performance will provide the best return on investment. A low-grade OTDR will result in higher risk and, ultimately, higher cost.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.