Categories

New Products

LDC-100 Large Diameter Optical Fiber Cleaver * Applicable to cladding diameter 80μm~1250μm fibers * Vacuum pump V-groove convenient to put fiber * Durable blade, lifetime more than 20000 times * Data storage 4000 groups * User friendly GUI menu, easy to operate more

S-22 Multi-Core Fiber Fusion Splicer The 1st Fully Automatic Multi-core Fiber Fusion Splicer in China more

Polarization Maintaining (PM) Fiber Fusion Splicer S-12 *Suitable for SM/MM/PM fibers splicing * Core to core alignment, low splicing loss * Endview and Profile observation and alignment * Arc automatic calibration and splicing * PM fiber 45 and 90 degree alignment * Applicable to variety fibers splicing, such as Panda ,bow-tie and elliptical fiber more

S-37 LDF Speialty Fiber Fusion Splicer SHINHO S-37 is the latest model we developed, it could splice fiber cladding diameter from 125 to 680μm with low splice loss. We equipped the machine with 3 different fiber holders, and 2 pairs of spare electrodes. more

Core to Core Alignment Fiber Fusion Splicer X900 Six motors fusion splicer, real core to core alignment technology. Typical splicing time: 6-12 seconds, fast splicing 6 seconds Typical heating time: 18s heating, identify fiber types automatically. Typical splice loss:G651: 0.01dB; G652: 0.02dB; G653: 0.04dB; G654: 0.04dB; G.655:0.04dB; G657:0.02dB. Battery Capacity: 5200mAh Li-battery, typical 300 cycles splicing and heating. Used for WAN/ MAN/ Telecommunication projects. more

Robust Multi Function ARC Fusion Splicer S16 76cm dropping anti-shock, IP5X dustproof and IPX2 water resistant Touch screen display, combined with keypad operation Multi function holder for bare fiber, patch cords, drop cable etc. Fast splicing and heating, automatic ARC calibration. more

SHINHO X-18 Ribbon Fiber Thermal Stripper Shinho X-18 Thermal Stripper is a newly developed hand-held thermal stripper, specially designed for nondestructive thermal stripping of the jacket of ribbon cable up to 12 fibers. A good and reliable tool for ribbon fiber splicing work. more

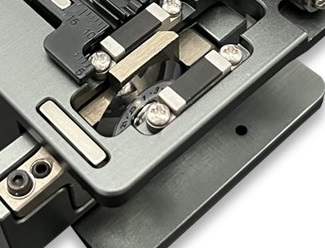

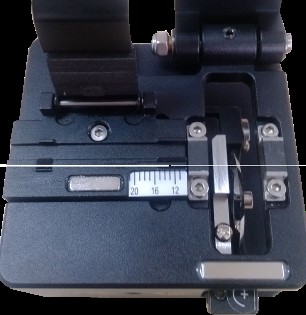

High Precision Fiber Optic Cleaver X-50D Small size& light weight, easy to operate. High precision and stable performance. More than 48000 time blade life,fiber cleaved length 5~20mm. High quality material more

What causes high fusion losses?

In the daily use of the fusion welding machine, someone complain that: just recently maintained the machine, electrodes are replaced with new ones, and discharge correction has been done. Why the fiber fusion loss still not reduced?

This

situation is often closely related to the user's operating practices. A fusion

splicer is a precision instrument that splices optical fibers with minimal loss

under optimal operating conditions, but only if there is a flat, clean cut end-face

of fiber, and achieving this operating condition requires standard operating

procedures and ways.

Today, we will learn about the reasons that may lead to fiber splicing failures.

First,

there are possible reasons for pollution:

1,

Didn't clean the fibers very well, stripping fiber directly after the hand.

(Clean

the optical fiber with anhydrous alcohol after stripping the fiber coating

layer)

2,

The use of a contaminated cutting knife

(Use

a cotton swab dipped in alcohol to wipe the cutting knife )

3,

Wiped the fiber again after cutting

(Never

wipe the optical fiber after cutting)

4,

The V-groove accumulates dust, which leads to unstable optical fiber movement

and high fusion splicing loss.

(Cleaning V-groove, use a cotton swab soaked in alcohol to clean the upper surface and bottom of the V-shaped groove, and finally wipe the alcohol in the V-shaped groove with a dry cotton swab. Be careful not to leave lint.)

5,

Dusts on the fiber clamp chip will lead to unstable fiber clamping and affect

the quality of the splice.

(The

fiber presser foot should be clean regularly. )

Second, the reasons that may lead to fiber fragmentation are:

1,

Poor cutting quality, directly leading to fragmentation

(Rotate

to a new knife surface, or adjust the blade height)

2,

The fiber optic end face touches something else

(After

cutting the fiber, do not let the fiber optic end face touch any more objects )

Third,

the causes of poor fiber cutting are:

1,

The optical fiber is not placed perpendicular to the cutting knife surface

(Make

sure to place the optical fiber in the slot of the cutting knife fixture)

2,

The fiber optic coating is placed on the rubber mat.

(Put

the fiber back a bit, what's left on the rubber mat should be the part with the

coating stripped off)

3、No force or too much force during the cutting process

(With

practice, you'll find that suitable range of force.)

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.