Categories

New Products

LDC-100 Large Diameter Optical Fiber Cleaver * Applicable to cladding diameter 80μm~1250μm fibers * Vacuum pump V-groove convenient to put fiber * Durable blade, lifetime more than 20000 times * Data storage 4000 groups * User friendly GUI menu, easy to operate more

S-22 Multi-Core Fiber Fusion Splicer The 1st Fully Automatic Multi-core Fiber Fusion Splicer in China more

Polarization Maintaining (PM) Fiber Fusion Splicer S-12 *Suitable for SM/MM/PM fibers splicing * Core to core alignment, low splicing loss * Endview and Profile observation and alignment * Arc automatic calibration and splicing * PM fiber 45 and 90 degree alignment * Applicable to variety fibers splicing, such as Panda ,bow-tie and elliptical fiber more

S-37 LDF Speialty Fiber Fusion Splicer SHINHO S-37 is the latest model we developed, it could splice fiber cladding diameter from 125 to 680μm with low splice loss. We equipped the machine with 3 different fiber holders, and 2 pairs of spare electrodes. more

Core to Core Alignment Fiber Fusion Splicer X900 Six motors fusion splicer, real core to core alignment technology. Typical splicing time: 6-12 seconds, fast splicing 6 seconds Typical heating time: 18s heating, identify fiber types automatically. Typical splice loss:G651: 0.01dB; G652: 0.02dB; G653: 0.04dB; G654: 0.04dB; G.655:0.04dB; G657:0.02dB. Battery Capacity: 5200mAh Li-battery, typical 300 cycles splicing and heating. Used for WAN/ MAN/ Telecommunication projects. more

Robust Multi Function ARC Fusion Splicer S16 76cm dropping anti-shock, IP5X dustproof and IPX2 water resistant Touch screen display, combined with keypad operation Multi function holder for bare fiber, patch cords, drop cable etc. Fast splicing and heating, automatic ARC calibration. more

SHINHO X-18 Ribbon Fiber Thermal Stripper Shinho X-18 Thermal Stripper is a newly developed hand-held thermal stripper, specially designed for nondestructive thermal stripping of the jacket of ribbon cable up to 12 fibers. A good and reliable tool for ribbon fiber splicing work. more

High Precision Fiber Optic Cleaver X-50D Small size& light weight, easy to operate. High precision and stable performance. More than 48000 time blade life,fiber cleaved length 5~20mm. High quality material more

What is Return Loss for Fiber Connectors?

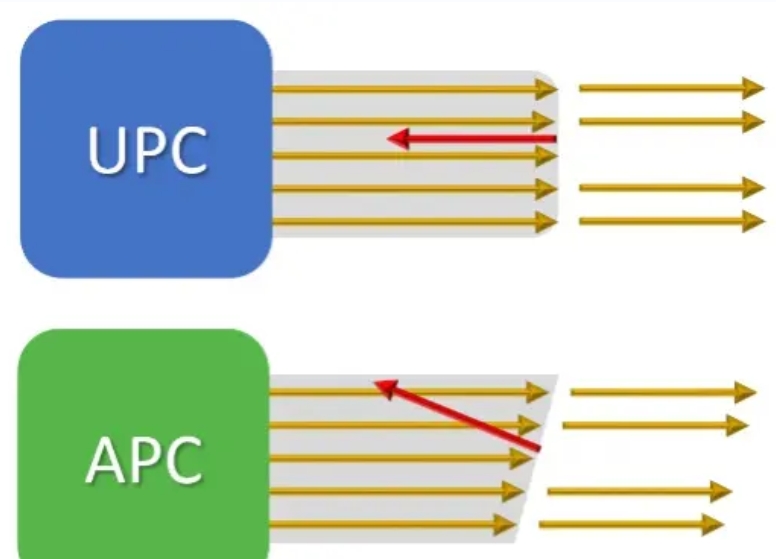

Return loss is the amount of optical power reflected in the source due to a mismatch between the connector and the fiber. It is expressed in decibels (dB) and is caused by factors, such as surface imperfections, fiber core diameter variations, and axial misalignments. Return loss can lead to signal interference, distortion, and reduced transmission distance.

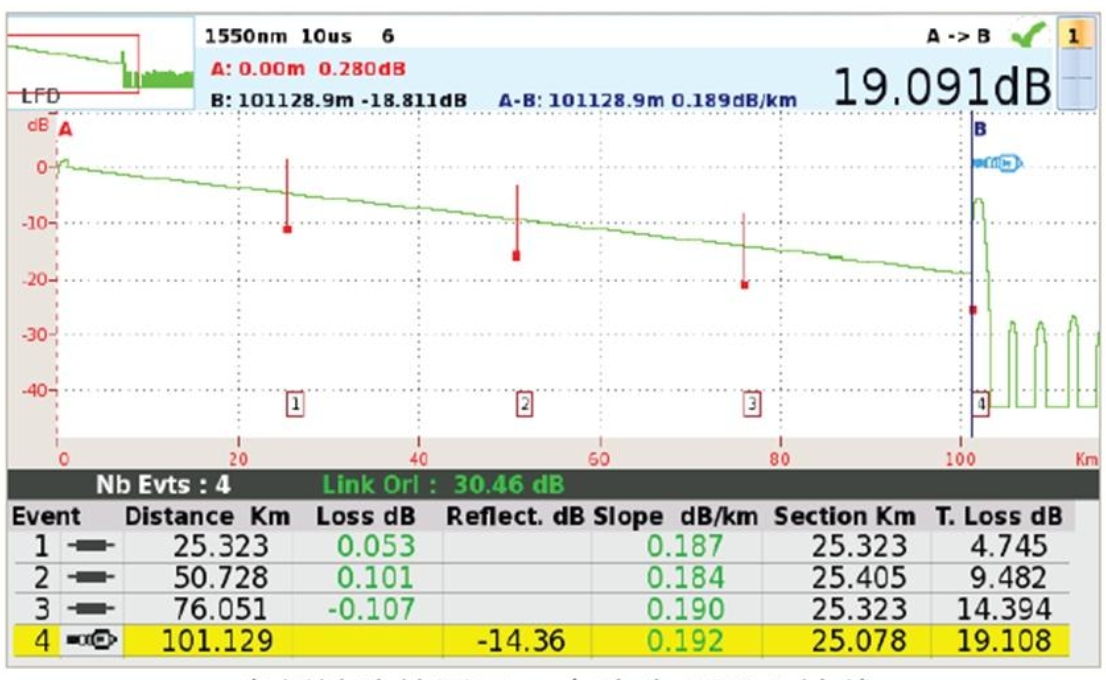

The most common method used to measure return loss is the Optical Time Domain Reflectometer (OTDR). Here are the steps involved in measuring return loss using an OTDR:

1. Connect the OTDR:

Connect the OTDR to the fiber optic connector being tested.

2. Measure the Reference Signal:

Measure the reference signal by connecting the OTDR to a reference cable. The reference cable should have a known length and be properly calibrated.

3. Measure the Test Signal:

Measure the test signal by connecting the OTDR to the connector being tested. The OTDR sends a pulse of light down the fiber, and the reflections are analyzed.

4. Analyze the Results: The OTDR produces a trace of the reflected light. Analyze the trace to determine the amount of return loss. The result is expressed in decibels (dB).

Using well-tested, high-quality connectors can help network installers provide high-speed connections that perform well over the long term. Here are some tips for optimizing insertion/return loss values:

1. Keep all fiber optic connectors clean, especially before and after installation and testing.

2. Minimize the number of tight bends, coils, splices, and connectors that can cause light to refract through the fiber cladding. If coiled fibers are required, keep the radius as large as possible.

3. Use factory-terminated cables. These terminations are made according to strict guidelines and usually include a manufacturer's warranty.

4. Make an informed budgetary decision: your "power loss" budget or your cable inventory budget. Buying cheap fiber optic cables of poor quality can further add to the cost.

Return loss leads to reduced signal strength, interference, and signal distortion, which can result in errors and reduced transmission distance. Therefore, it is essential to minimize return loss to ensure reliable and efficient signal transmission.

Today is Dec 22, 2023, wish you Merry Christmas and Happy New Year.

© Copyright: SHINHO OPTICS LIMITED All Rights Reserved.